Bora recognizes the growing challenges and responsibilities brought by climate change and is committed to reducing greenhouse gas emissions. Aligned with the TCFD framework, we disclose our governance, strategies, and risk management practices related to climate issues. Each year, we conduct carbon inventories, develop carbon reduction plans, and implement targeted actions to lower our operational carbon footprint. These efforts not only meet market stakeholder and customer expectations but also enhance our long-term competitiveness.

Environmental Objectives and Policy

A. Environmental Goal

- In response to the global push for net-zero emissions by 2050, Bora Group has made energy saving and carbon reduction a core objective. We are committed to mitigating the impacts of climate change while promoting environmental protection and sustainable development.

- Starting in 2025, we implement the ISO-14001 environmental management system to establish a comprehensive, top-down approach to managing environmental, safety, and health policies.

B. Environmental Policy

- Conduct carbon inventories and disclose emissions data across all subsidiaries.

- Use the carbon inventory system to identify reduction opportunities across internal and external operations.

- Promote green supply chains for consumers and customers.

- Consider product life cycle foot points, from raw materials to disposal.

C. Our Goals

| Term | Goal |

|---|---|

| 2025-2030 Short-term goals |

|

| 2031-2040 Mid-term goals |

|

| 2041-2050 Long-term goal |

|

Environmental Management System Certification (ISO 14001)

Bora Pharmaceuticals is dedicated to green sustainability and actively implementing environmental management systems. Currently, the Parent Company of Bora Pharmaceuticals has successfully obtained the ISO 14001:2015 certification, issued by the third-party certification body, ARES International Certification Co., Ltd.

The validity period of this certificate is from December 4, 2025, to December 3, 2028. We are committed to continuously optimizing our environmental performance through the P-D-C-A management cycle. Furthermore, we plan to progressively implement this environmental management standard across all facilities within the group, demonstrating our concrete commitment to sustainable corporate development.

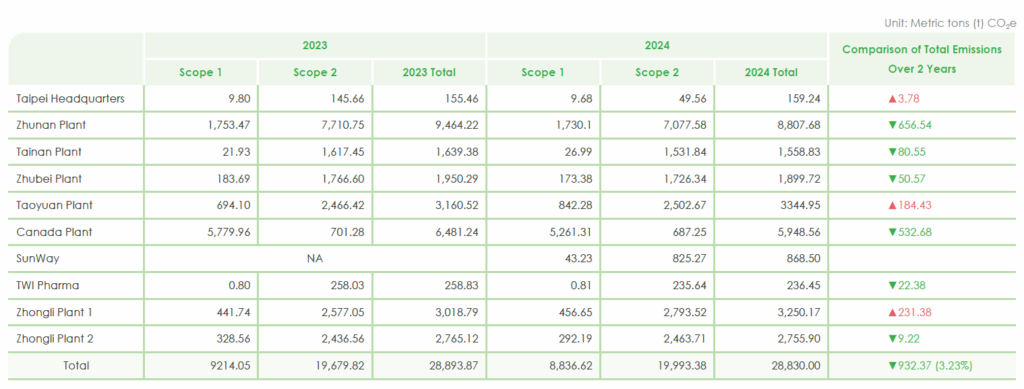

Greenhouse Gas Emissions

Since 2021, Bora has adopted the ISO 14064-1:2018 greenhouse gas (GHG) inventory standard and engaged a third-party organization for annual verification. We have successfully obtained verification certificates for 3 consecutive years. Starting in 2023, we used GHG emissions data as the baseline for setting reduction targets and will continue implementing carbon reduction measures across our operations.

Compared to 2022, Bora’s 2023 GHG emissions showed noticeable changes. The increase was mainly driven by:

- Inclusion of the Zhubei and Zhongli Plant 1 and 2 facilities.

- Expanded emissions calculation boundaries.

- Shifts in production scale.

All emissions from newly integrated facilities have been fully accounted for in 2023, Sunway Biotech, which was integrated into Bora at the end of 2023, is still undergoing data integration and will be included in the 2024 report.

Internal Carbon Pricing

To effectively assess climate risks and internalize environmental costs, Bora Pharmaceuticals is introducing an Internal Carbon Pricing (ICP) mechanism. This mechanism will be piloted at our Taiwan sites starting in 2026. The pricing basis references the rate set by the Taiwan Ministry of Environment, established at NT$300 per metric ton, utilizing a “Shadow Price” model.

We incorporate the shadow price into the decision-making process for carbon reduction projects by adding a cost-benefit analysis of the shadow carbon fee to existing project evaluation forms. Furthermore, at the end of the year, we verify the actual effectiveness of these reduction projects and calculate the saved shadow carbon costs, thereby quantifying the financial benefits of decarbonization investments and driving our low-carbon transition.

Energy Management

Bora is committed to reducing overall energy consumption to lower carbon dioxide emissions. The main energy sources across the Bora Group are purchased electricity and natural gas. We do not use heavy oil or diesel. Electricity powers chiller units, air conditioning systems, and production equipment within our facilities. Natural gas is primarily used for gas boilers.

Energy Consumption (GJ)

| Energy Type | 2023 | 2024 |

|---|---|---|

| Purchased Electricity | 222,447.73 | 229,080.47 |

| Gasoline | 106.79 | 126.79 |

| Diesel | 260.21 | 449.76 |

| Natural Gas | 149,188.69 | 127,119.67 |

| LPG | 531.54 | 610.63 |

| Total | 372,534.96 | 357,387.32 |

Fulfilling Environmental Commitments

Bora Pharmaceuticals is dedicated to implementing environmental sustainability with a clear long-term decarbonization goal: to reduce Scope 1 and Scope 2 carbon emissions by 30% by 2030 compared to the baseline year. To ensure this goal is met, we require each site to achieve an annual carbon reduction of at least 3%.

In terms of execution, our EHS department records and monitors carbon emission data on a monthly basis to ensure data transparency and real-time management. Furthermore, Bora has established a cross-border communication platform. In addition to holding internal review meetings respectively, our Taiwan and North American sites regularly exchange reduction results and technical experiences. Through this transnational cooperation and resource sharing, we jointly formulate and optimize our annual decarbonization actions.

| Year | Factory/Plant | Resources Invested | Achievements/Results |

|---|---|---|---|

| 2024 | Zhunan Facility | NTD 430,000 | By adjusting and optimizing the operation of the air conditioning system within the plant—such as modifying airflow for parallel operation, adjusting air exchange rates and dust collection airflow, and altering the operating frequency of cooling towers—we successfully reduced electricity consumption. Compared to 2023, the plant’s total electricity usage decreased by 811,600 kWh, representing a 6.62% reduction. Simultaneously, carbon emissions were reduced by 481 tons of CO2e, equivalent to an annual emission reduction of 5.48%. |

| 2024 | Tainan Facility | NTD 75,000 | By installing energy-saving devices on the adsorption dryer and completing installation and testing in April 2024, the Tainan plant successfully reduced its total electricity consumption by 4.63% from May onwards compared to 2023. This equates to a reduction of 8.3 tons of CO2e. |