Cutting-Edge Technology to Accelerate High-Volume Production; Mississauga Site to be Outfitted with Tube Filler this July

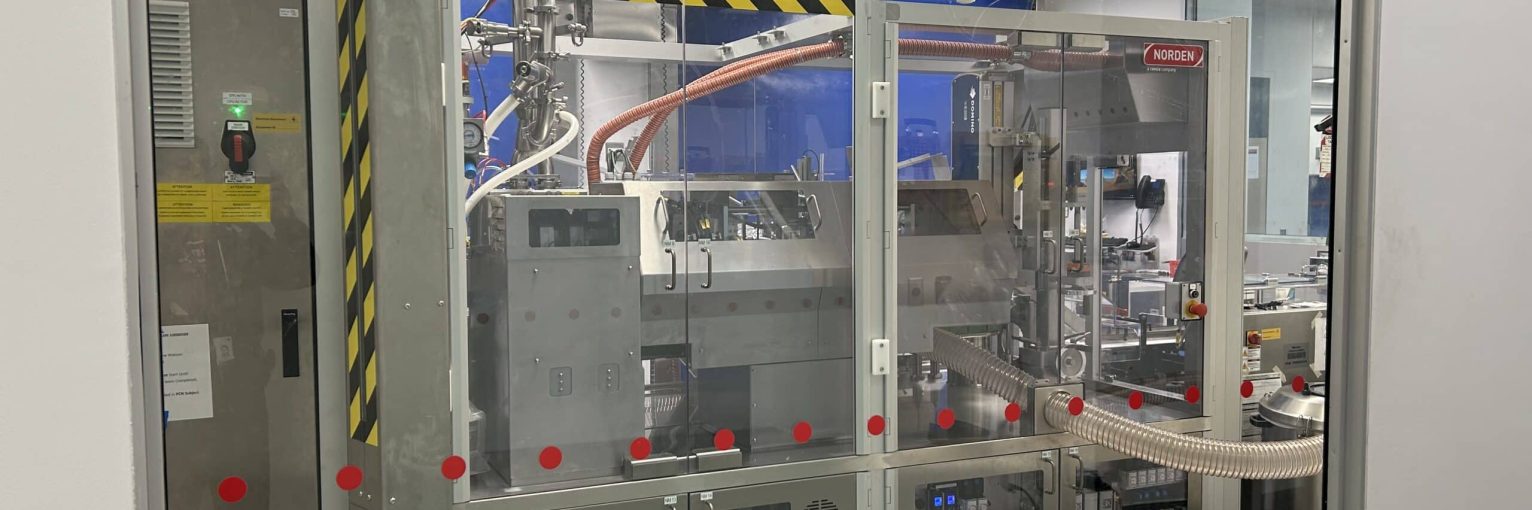

Mississauga, Ontario (July 16, 2025) – Bora Pharmaceuticals Co., Ltd. (“Bora” or “the Company”, TWSE: 6472), a global leader in pharmaceutical manufacturing, has announced a recent investment to install a high-performance filling line from Norden Machinery at its Mississauga, Ontario manufacturing facility. The new line expands Bora’s production capabilities, enabling larger volumes at higher speeds with greater flexibility, particularly for dermatologic products. The investment comes as the global dermatology drugs market is projected to nearly double in value to over $70 billion by 2030, reflecting the rising demand for high-quality, specialized treatments.

The new Norden filler is the third tube-filling line at the site and is capable of producing approximately 7 million to 15 million units per year, increasing the site’s total production capability to more than 50 million units annually. It can handle metal, plastic, and ABL tubes and includes laser printing capabilities, making it especially suited for the needs of dermatologic applications. The upgraded line is fully kitted out to pack the tubes into a wide range of cartons, then bundle, and automatically pack into shipping cases. The line is qualified for PODA and Track and Trace serialization, allowing more than 20+ of Bora’s markets to be packaged on this line.

“This filling line complements our deep expertise in semi-solid formulations and strengthens our ability to help customers scale up efficiently,” shared John Lawrie, VP of Operations for Bora Pharmaceuticals. “The upgrade significantly expands our capacity, allowing us to address growing demand for high volume production not just from our current partners, but from the marketplace as a whole.”

The system can accommodate a wide range of fill volumes, from 2g to 150g, and further supports scalability in the wide range of manufacturing vessels, specifically for semi solid manufacture that range in size from 2.5Kg to 3600Kg. This flexibility enables Bora to accommodate a variety of customer needs, all while maintaining cost efficiency and quality. The facility is also routinely inspected by multiple global regulatory agencies, with products currently exported to a growing number of regions, including North, Central, and South America; Europe; Asia; Russia; the Middle East; and Australia.

Bora’s Mississauga site is one of seven cGMP manufacturing sites that deliver drug products to more than 100 countries. The company’s commercial on-time, in-full (OTIF) delivery record is unmatched, reinforcing Bora’s role as a genuine partner, supporting clients with secure, consistent supply. For more information, visit boracdmo.com

About Bora Pharmaceuticals

Bora Pharmaceuticals is a premier international contract development and manufacturing organization (CDMO) specializing in formulation development, clinical and commercial manufacturing, and packaging of complex oral solid dose, liquid, semi-solid, biologics, and sterile injectable pharmaceutical products. From our world-class sites in North America and Asia, we deliver drug products with unparalleled quality to more than 100 markets around the world. For more information, visit www.boracdmo.com.